Снижение массового расхода на СО2 до 32-40% для очистки сухим льдом с ИРБИСТЕХ

Комплекс для очистки сухим льдом с минимальной себестоимостью

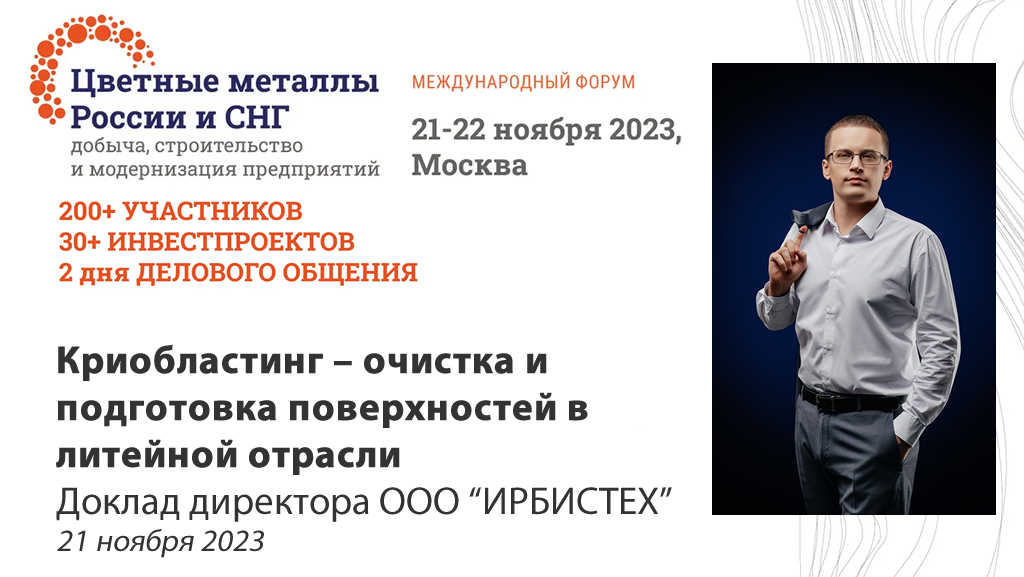

ИРБИСТЕХ представляет эффективные решениядля очистки сухим льдом и производства сухого льда

Промышленные установки для криобластинга II-поколенияОтличаются от I-поколения более высокой надежностью, безопасностью и удобством работы. Ультрасовременная система подачи гранул на базе порционного вала с каркашками от 2018 года.

ONE 2.0Криобластер II поколения только для мелких 3 мм гранул

TRANSFORMER 2.0Криобластер II поколения с запатентованным вариационным измельчителем крупных гранул (от 3 до 20 мм)

Преимущества встроенного измельчителя:

- Снижение испарения крупных гранул

- Крупные гранулы не слипаются как 3 мм гранул

- Более экономный расход гранул за счет измельчения

- Меньшее потребление сжатого воздуха при использовании более узких сопел

Цена: по запросу

Промышленные установки для криобластинга I-поколенияВключают все необходимые функции для мощной очистки сухим льдом. Надежная система подачи гранул на базе порционного вала с каркашками от 2002 года.

ONEКриобластер только для мелких 3 мм гранул

TRANSFORMERКриобластер с запатентованным вариационным измельчителем крупных гранул (от 3 до 20 мм)

Преимущества встроенного измельчителя:

- Снижение испарения крупных гранул

- Крупные гранулы не слипаются как 3 мм гранул

- Более экономный расход гранул за счет измельчения

- Меньшее потребление сжатого воздуха при использовании более узких сопел

Цена: по запросу

Установки для локального криобластингаВключают минимальный функционал для уверенной очистки сухим льдом.

МиниКриоБластер GT 2.0 Идеальное решение для точечной агрессивной очистки

- Ротор с защитой от влаги

- Давление очистки до 6 атм

- Расход гранул 30 кг/час

- Система "антислипания" гранул

- Большой бункер с защитной сеткой

- Ручка для подвешивания шланга и рукоятки

Цена: 520 000 руб. с НДС

Установки для локального криобластингаВключают необходимый функционал для очистки снегом СО2 от баллона с жидким СО2.

Бластер жидкого СО2Самый легких и компактный бластер жидкого СО2 в мире!

- Давление очистки до 10 атм (встроенный регулятор)

- Расход жидкого СО2: 0-80 л/час (регулируется вентилем)

- Полностью пневматическое устройство (не требует электричества)

- Вес: 6,5 кг (на лямке)

- Плоское сопло для очистки

Цена: 230 000 руб. с НДС

Гранулятор для производства гранул сухого льда с гибким масштабированием производительности (III-поколение)

Гранулятор PU20A-IIIПроизводите гранулы с производительностью от 20 до 180 кг/ч с экономией жидкого СО2

Экономия жидкого СО2 до 15%

За счет отсутствия экструдирования гранул и закрытой камеры прессования.

В III поколении появились следующие улучшения, которые повышают коэффициент конвертации:

- появился теплообмен "жидкий СО2 - выхлоп газа СО2" (к примеру, для производительности сухого льда в 100 кг/час площадь теплообмена составляет 4 квадратных метра);

- площадь фильтрации увеличилась в 5 раза;

- встроенный инновационный герметичный циркуляционный насос собственной разработки вместо циклического поршневого дискретного насоса с манжетными уплотнениями.

Высокая надежность

Использование пневмопривода прессования вместо гидравлики;

В III поколении появились следующие улучшения, которые повышают надежность:

- встроенный циркуляционный насос жидкого СО2 теперь полностью герметичный и не требует периодической замены каких-либо сальниковых уплотнений;

- единая пневматическая система на более простых общепромышленных компонентах;

ИННОВАЦИОННОЕ ПРОИЗВОДСТВО СУХОГО ЛЬДА

На базе российского оборудования

С высочайшим уровнем экономии жидкого СО2

Без технического надзора

Обновленная страница о компании ИРБИСТЕХ и о том как мы обеспечиваем высокое качество изготавливаемого оборудования

О рекомендациях как не стать жертвой мошенников по покупке некачественного оборудования

Нас поддерживают федеральные и региональные структуры

В периоды НИОКР компания была поддержана Фондом содействия инновациям, Инвестиционно-венчурным фондом РТ, Фондом Сколково, Министерством промышленности и торговли РФ.

Инновационность компании

В 2016 году компании присвоили статус резидента Фонда Сколково (свидетельство №1121487), что абсолютно говорит о том факте, что компания ИРБИСТЕХ является инновационной и ее технологии имеют мировое значение.

Исследования осуществляются при грантовой поддержке Фонда «Сколково»